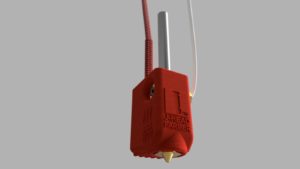

J-Head™ Farmer

$59.99

Description

J-Head™  Proudly Made Right In The USA

Proudly Made Right In The USA

Object Visibility

Kit Includes:

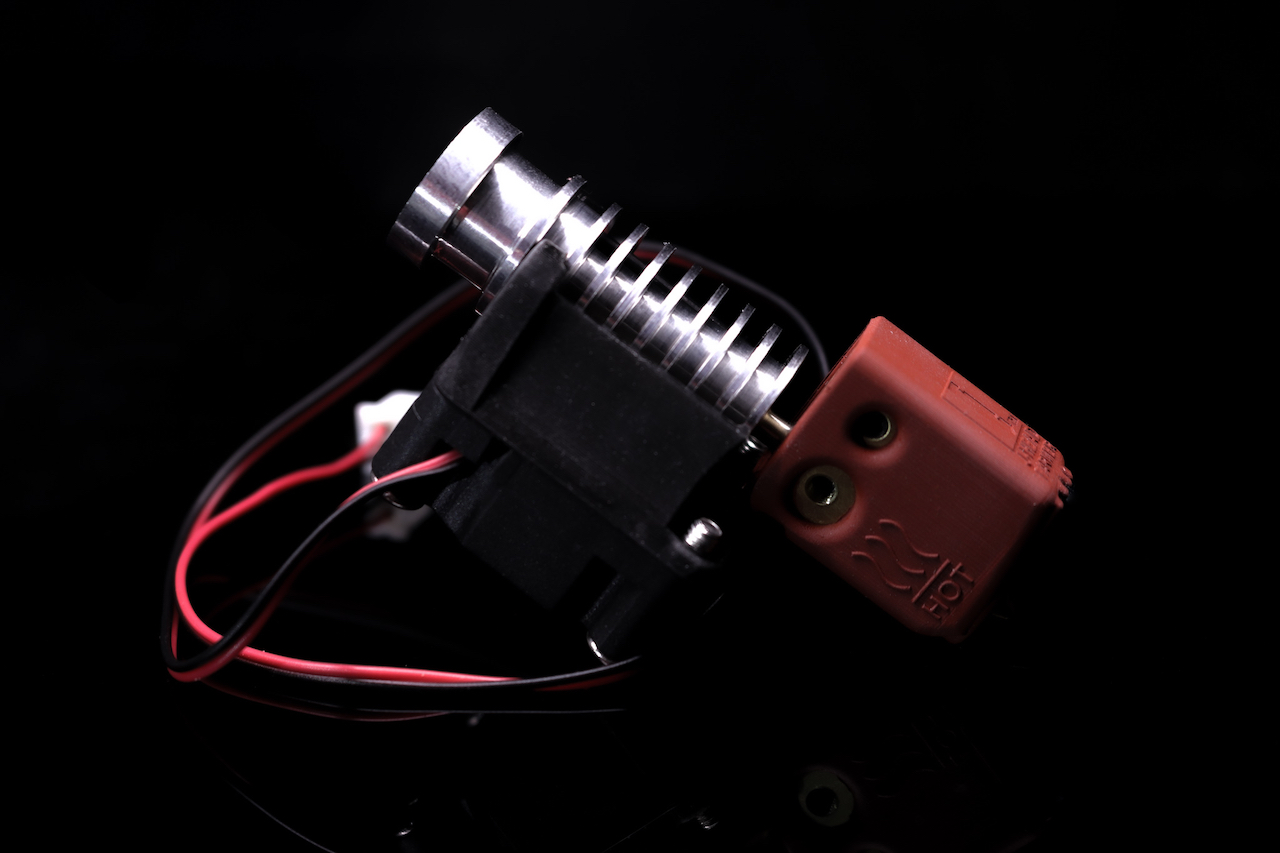

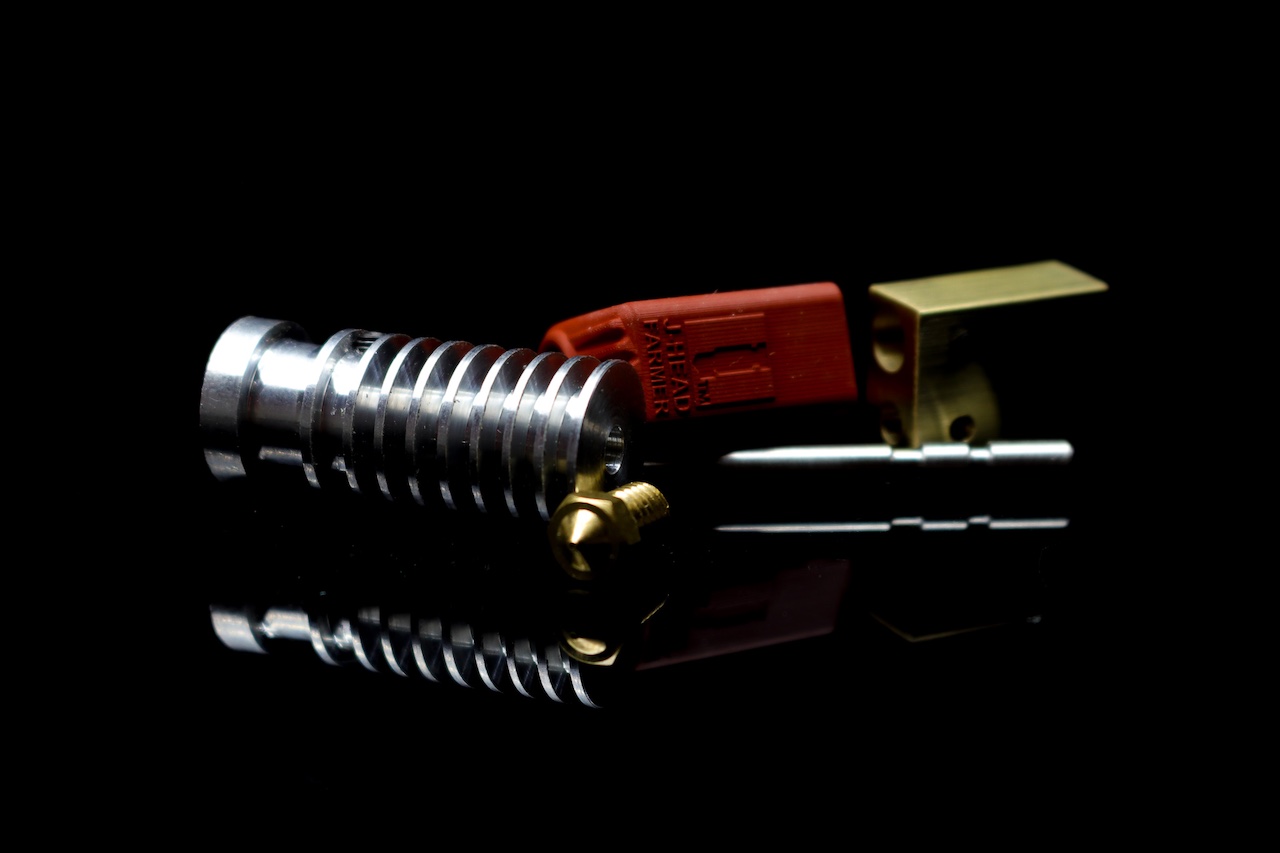

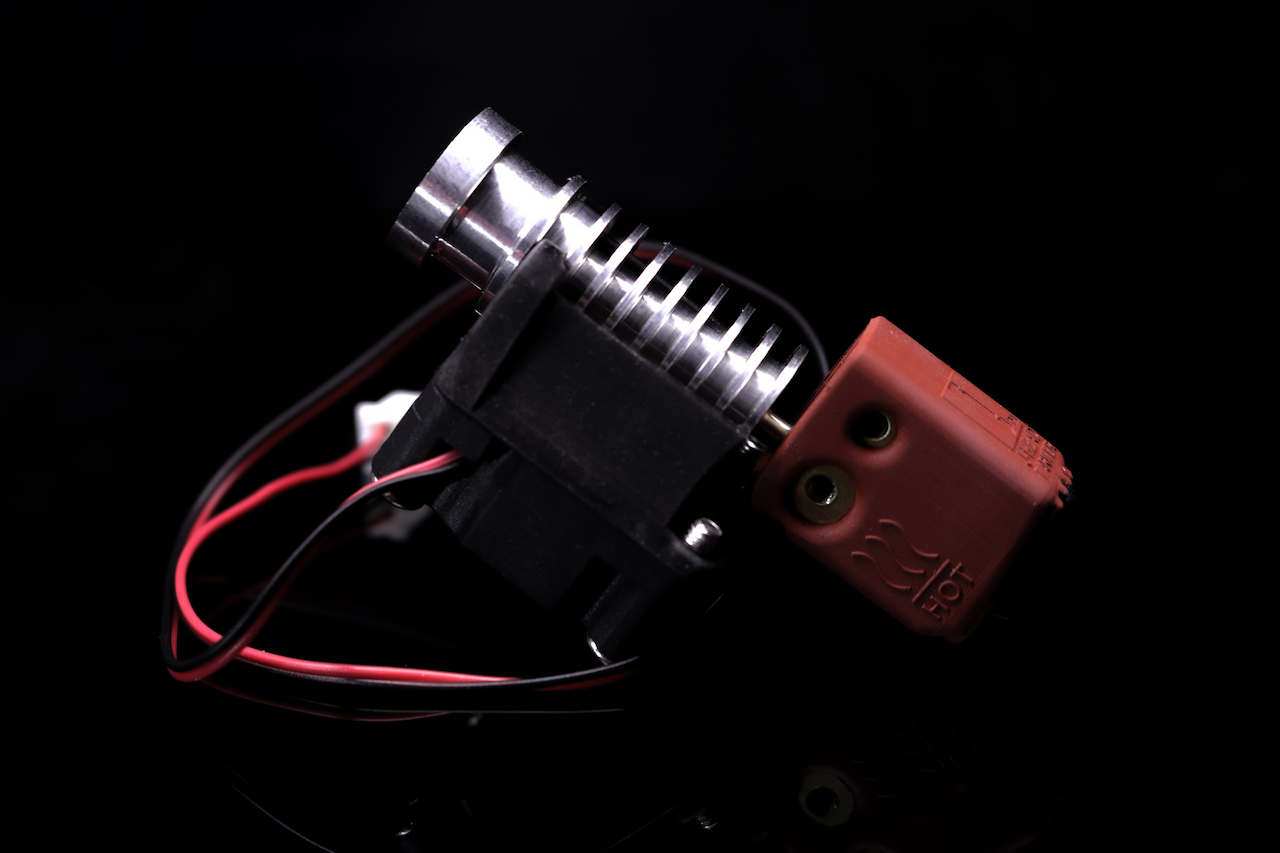

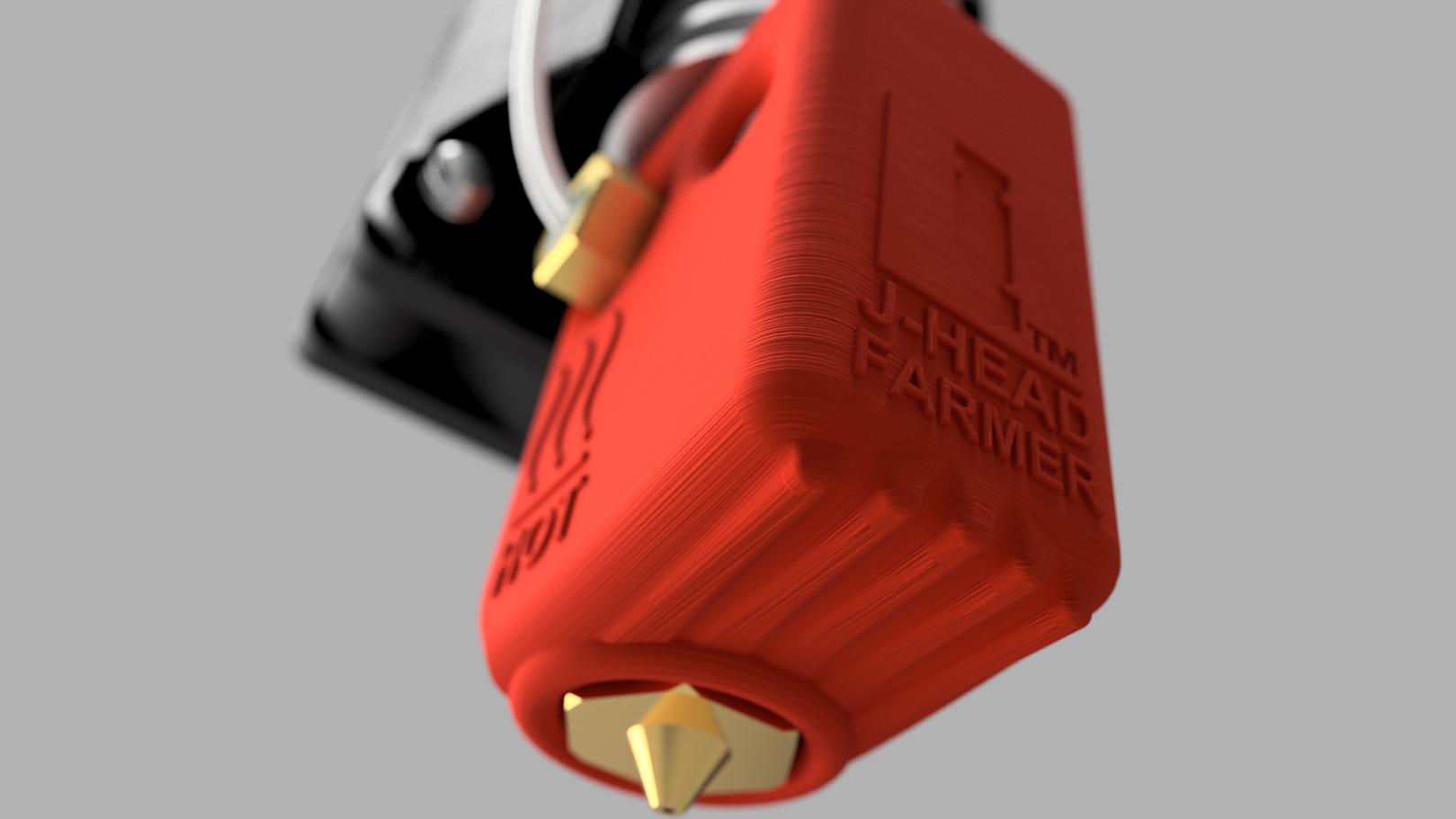

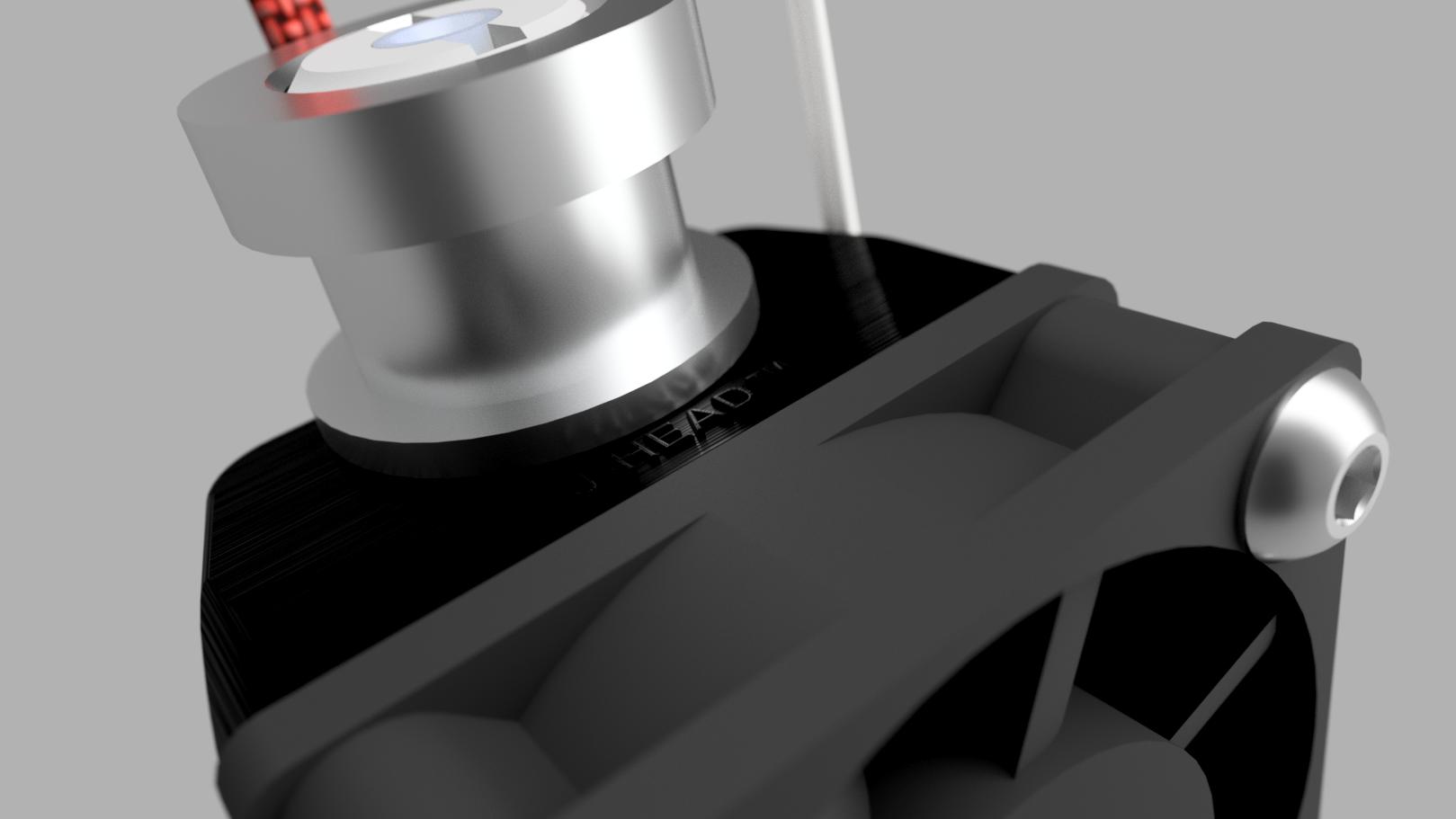

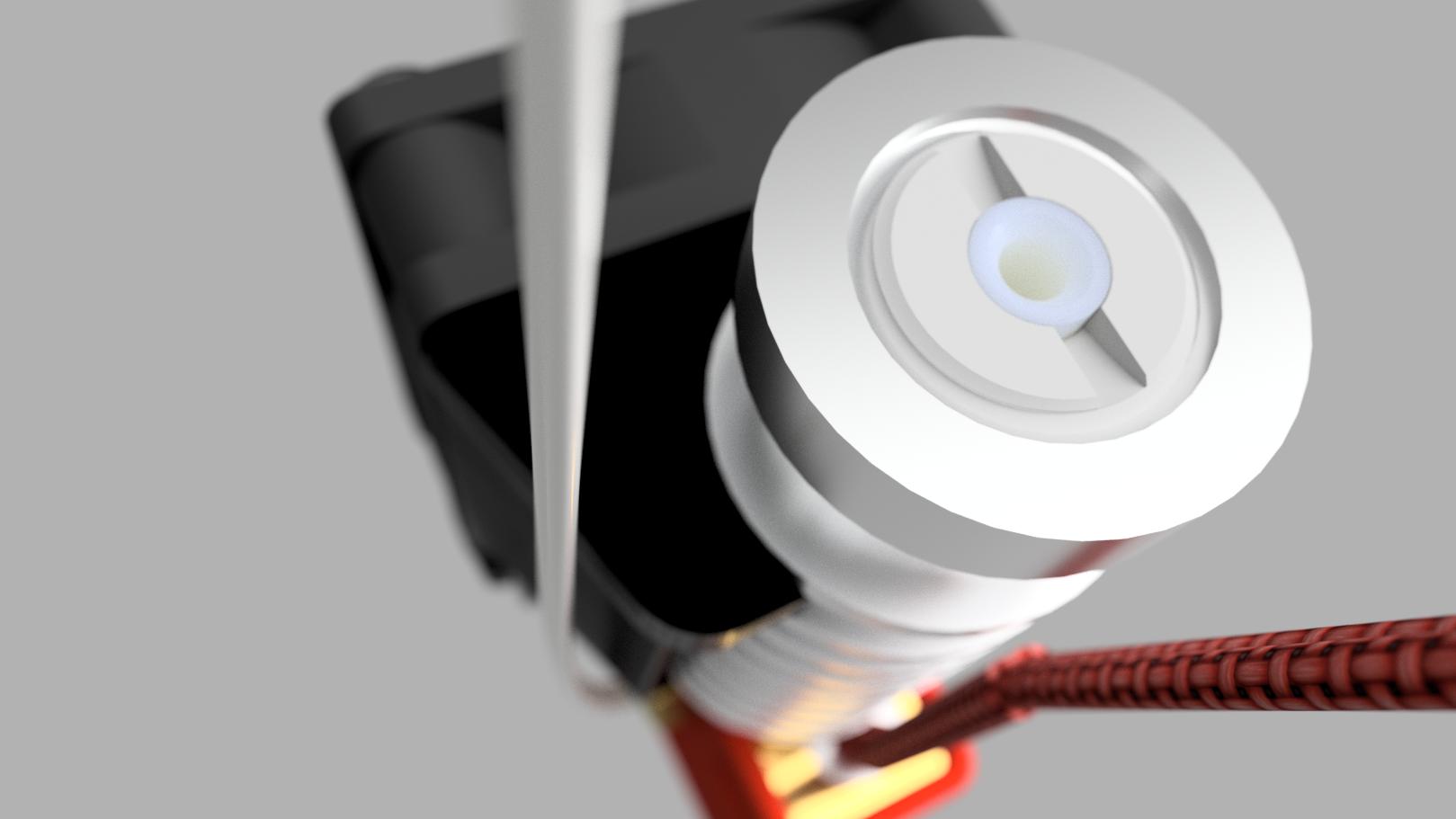

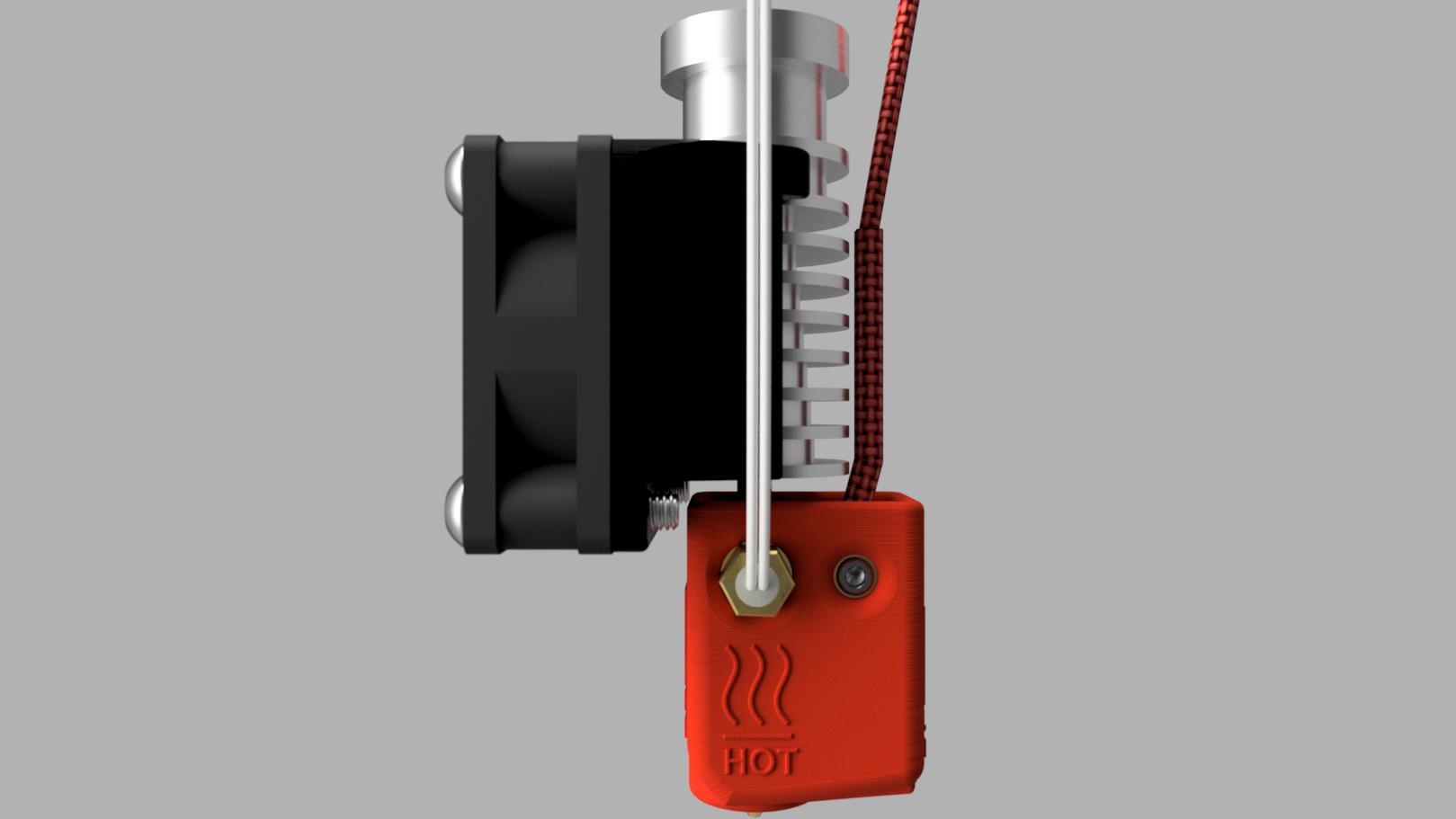

- 1x - J-Head™ Finstack

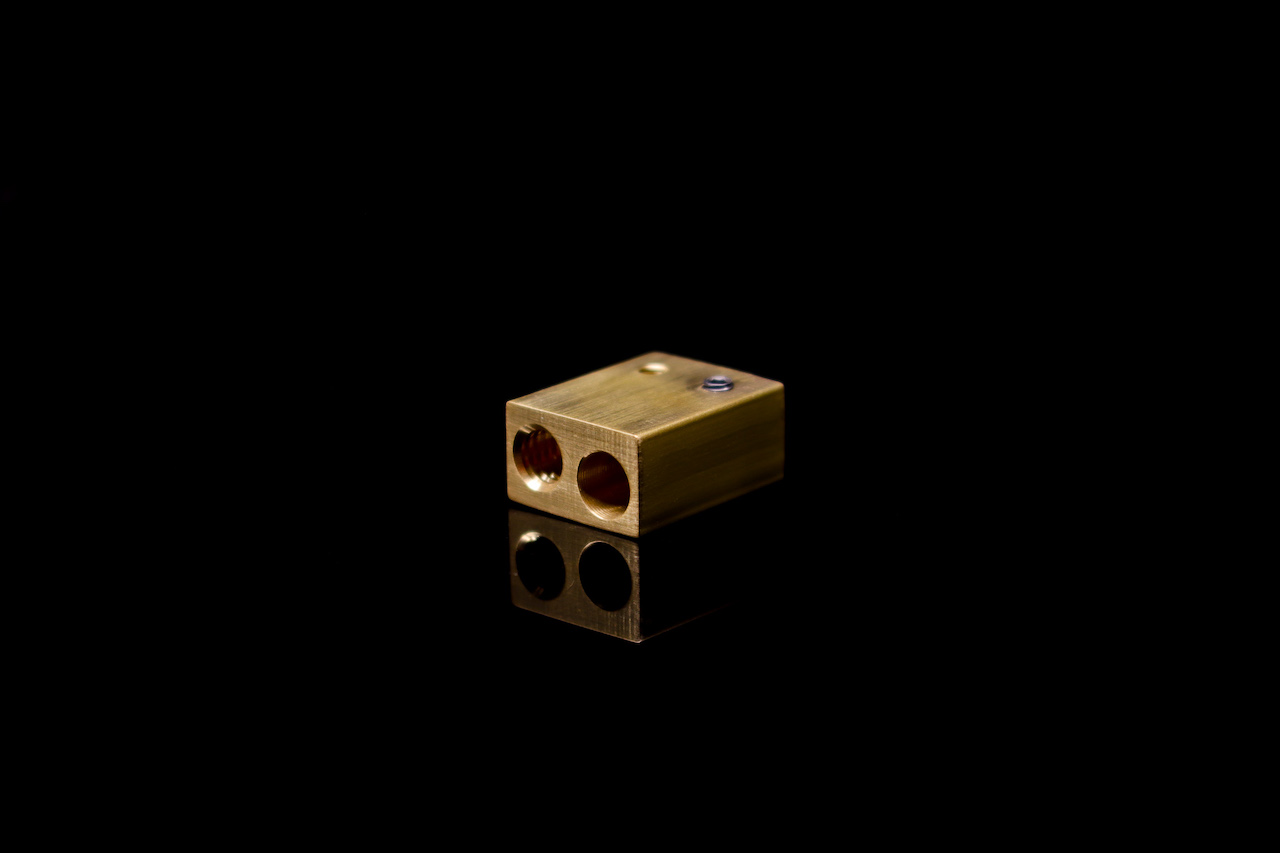

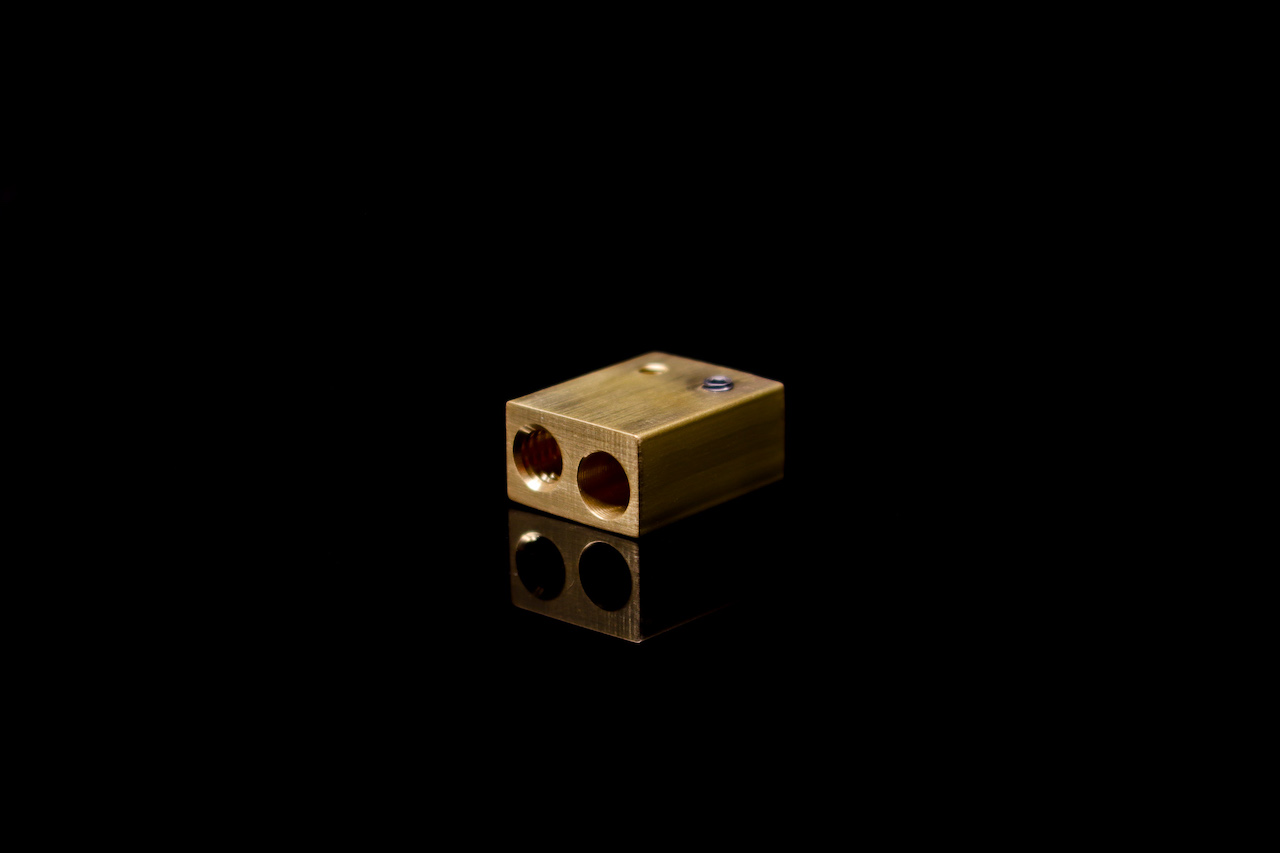

- 1x - J-Head™ Brass Heater Block

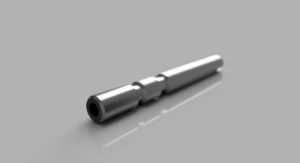

- 1x - J-Head™ Core Tube

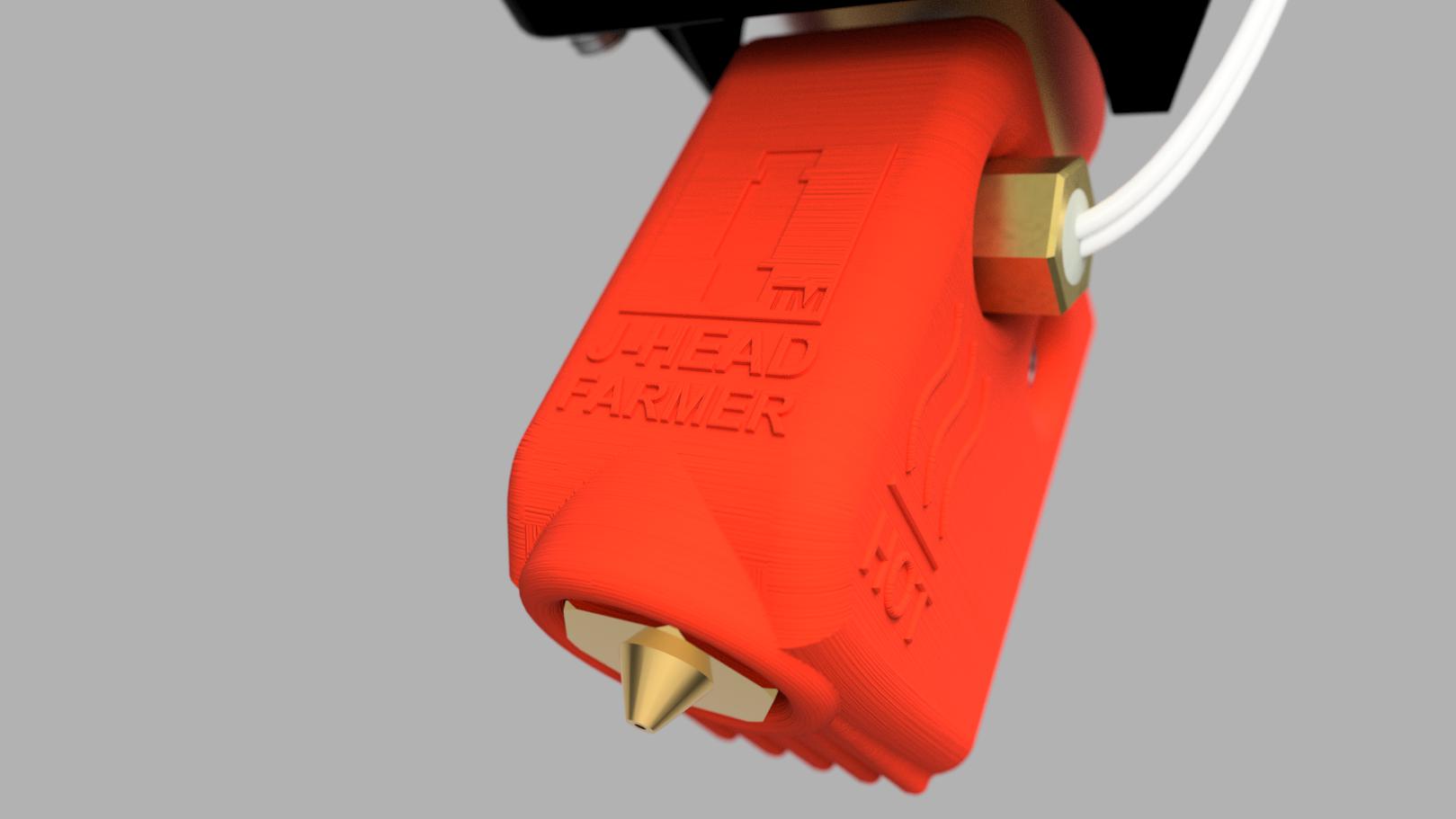

- 1x - J-Head™ Fan Shroud

- 1x - J-Head™ Silicone Sock

- 1x - J-Head™ Temp Probe - m3

- 1x - 12v/24v 40watt Heater Cartridge

- 1x - 12v/24v Fan

- 1x - 0.4 Nozzle

- 1x - 1.5mm Allen wrench

- 1x - 2.0mm Allen wrench

Dimensions:

- Body Diameter 16mm

- Mounting Groove to Nozzle Tip (L) 54mm* *Adjustable +/- 1mm

- Universal Top m10x1 threads

- Standard m6 Threaded Nozzle

Additional Information:

J-Head™ Farmer Datasheet

J-Head™ Farmer Assembly Guide

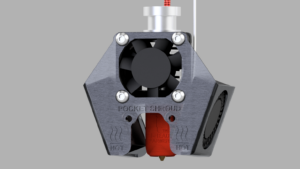

Photo Gallery:

Advantages:

- Extended length melt chamber *allows for faster print speeds and more!

- All Metal Construction - NO PTFE liner - Giving you access to printing from PLA to extreme high temperature PEEK materials!

- Adjustable length

- great for calibrating dual extruder setups.

- Eliminate The "Paper Test"

- Universal top featuring our new bowden Aglet™ fittings for zero backlash bowden tubes!

Compatability:

- Groove Mount

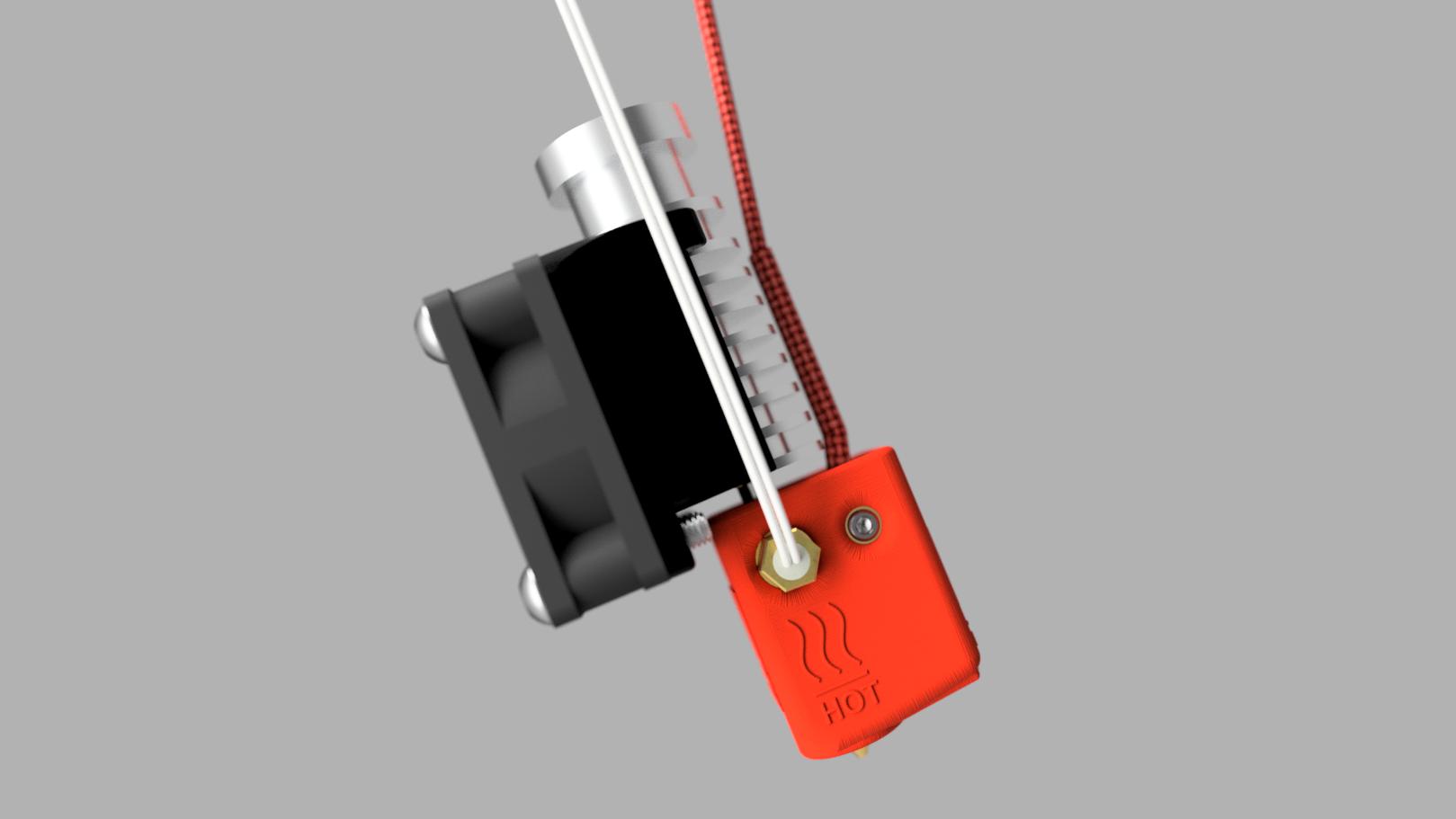

- J-Head™ Farmer hotend with its vertical heater cartridge is similar in length to our competitors *brackets, mounts and shrouds found on Thingiverse and other repositories should work without modification!

- Standard nozzles.

Print More, Tinker less, No Surprises.

What A Perfect Upgrade For Your 3D Printer Looks Like

Slice G-Code - Hit Print - Enjoy Your Creation!

J-Head™ Makes 3D Printer Maintenence One Less Thing To Worry About.

You spoke - We listened.

The new J-Head™ Farmer was designed for 3D Printer farms and YOU!

What Does That Mean?

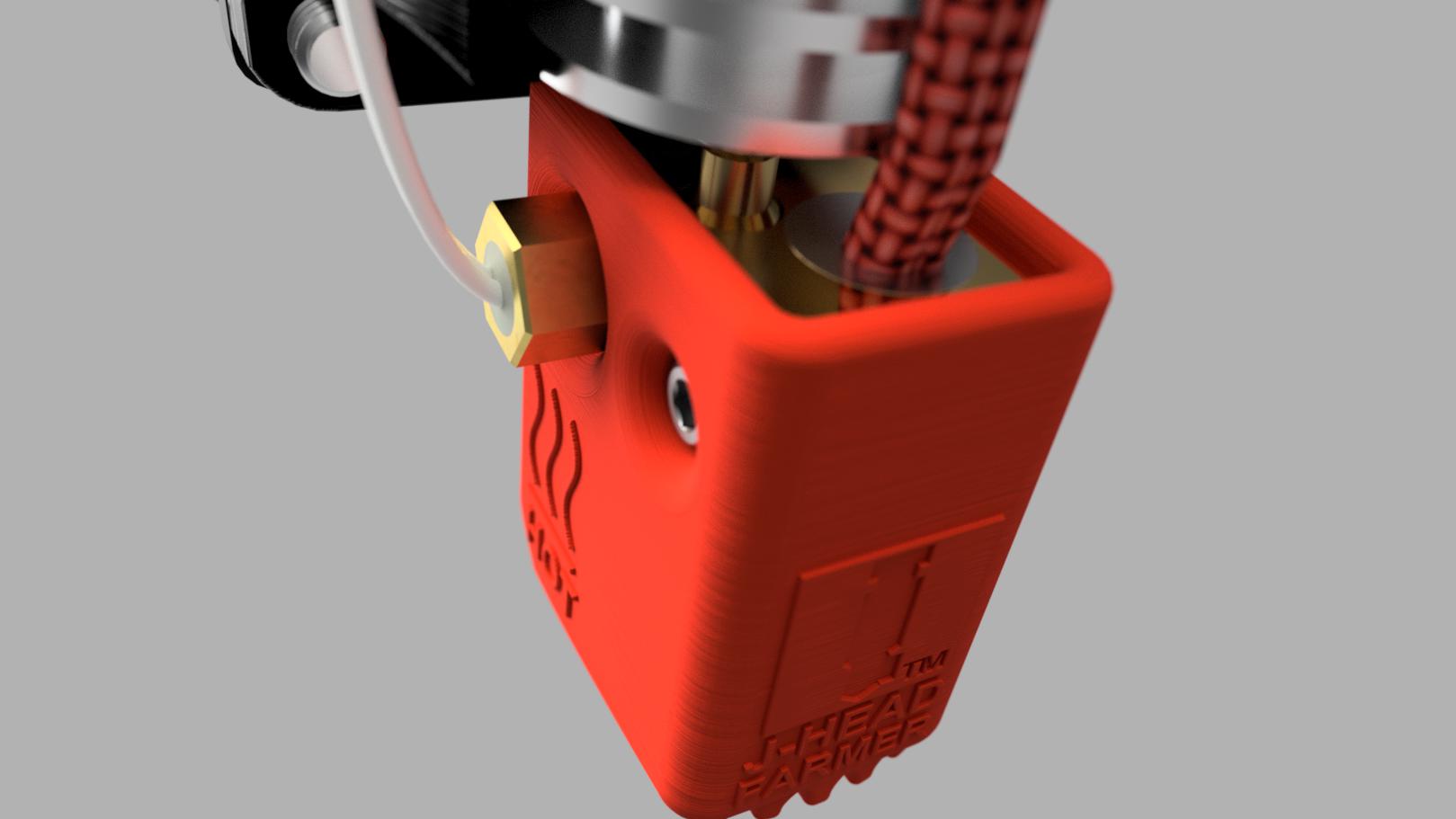

The J-Head™ Farmer can be dissassembled in stages All while it is still installed on your printer

No more hassle having to dissassemble your extruder or hotend mount to fix jams or clogged nozzlesYou Can Remove The Nozzle

Or You Can Drop The Heater Block Assembly

You Can Even Remove The Core Tube!

All Without Removing The Finstack From Your Extruder or Hotend Mount!

But what's really cool!...Just Pickup a spare J-Head™ Farmer Swap Kit The next time you have a filament jam or filament clog, you're covered!

Resume your print - then fix the jam or clog on the workbench in your own time

Less printer down-time!

J-Head™ Farmer Swap KitIt won't let you down - and neither will we!

Designed for reliability

We are the designers and the manufacturer. We hope you choose Genuine J-Head™ and we look forward to seeing you enjoy 3D Printing.Support

J-Head™ hotends was established in 2011, and since then we've constantly strived to provide stellar customer service with superior hotends to our community!Additional information

| Filament Diameter | 1.75 |

|---|---|

| Voltage | 12v, 24v |

| Weight | 30g |

| Drive | Direct Drive / Bowden |

| Height | 54mm |

| Construction | All-Metal |

| Nozzles | Standard Replaceable – ships with .4mm brass |

Reviews

There are no reviews yet.

Only logged in customers who have purchased this product may leave a review.